All our posters, cards and notebooks are printed using letterpress, the method of printing developed by Gutenberg in the 15th century. Although almost all printing is now done by off-set and digital techniques, we continue to use letterpress because of the quality, texture and definition of the final printed product. In this post we interview our most experienced printer, David Evans, and letterpress enthusiast, Ben Brundell. Ben's website is an authority on all matters letterpress.

What got you interested in printing?

Ben Brundell (BB): I’ve always been fascinated by letters and lettering. I made a small, typewritten and stencil-duplicated newspaper at primary school in the late 1980s and wanted an 'Adana' that I'd seen in the Exchange and Mart; but funds did not allow me to get a press. Moving forward to 2005, I went to a wedding and the rural pub had very distinct letterpress-printed bill-heads and I was transported back to 'Printing as a Hobby' that I read at primary school. I got a small Adana and the whole thing mushroomed from there.

David Evans (DE): I was heading for a career in agriculture when my Mum came back from the pub one day and said that she’d been talking to someone who knew a printer and he was looking for an apprentice. I arranged an interview, asked a few questions about what the job involved, and was put in a seat in front of a Linotype machine. Coming from a family of millwrights and engineers, I was fascinated and entranced by the motion and sound of the slides, cams and levers, and the distinctive smell of the hot metal. I can still sit and watch the motion of the machine some 40 years on!

Why is there so much interest in letterpress printing?

DE: The craft and its traditions going back 500 years, the skill, the precision, working with words, working with your hands, and the beauty of the final products.

BB: What's not to like?! To be a really good jobbing printer , you need to be at least competent at: writing with style; visual design with imagaination; mechanical engineering; planning and management; and all that before we start on the art of printing itself. I can't think of a more demanding craft. There are so many possibilities to explore! On top of that you actually handle and produce something rather than something that exists only on a screen.

What is your all time favourite printing press?

BB: It would have to be the Halifax-built Arab platen press. Very much a product of its time and place but still working hard. I meet printers now that undertake commercial work on an Arab, it's a machine that's very adaptable, versatile and does the same job today as it was designed for 141 years ago!

DE: There were and are many fascinating machines used in the printing trade. It’s not a press as such, but my favourite has to be the Linotype machine

Why is there so much interest in letterpress printing?

DE: The craft and its traditions going back 500 years, the skill, the precision, working with words, working with your hands, and the beauty of the final products.

BB: What's not to like?! To be a really good jobbing printer , you need to be at least competent at: writing with style; visual design with imagaination; mechanical engineering; planning and management; and all that before we start on the art of printing itself. I can't think of a more demanding craft. There are so many possibilities to explore! On top of that you actually handle and produce something rather than something that exists only on a screen.

What is your all time favourite printing press?

BB: It would have to be the Halifax-built Arab platen press. Very much a product of its time and place but still working hard. I meet printers now that undertake commercial work on an Arab, it's a machine that's very adaptable, versatile and does the same job today as it was designed for 141 years ago!

DE: There were and are many fascinating machines used in the printing trade. It’s not a press as such, but my favourite has to be the Linotype machine mechanical typesetting machinery here >.

What's the best piece of work you've ever produced?

BB: I was especially pleased with the printing I did for my wedding! I didn't have time to fulfil all of my ideas for the day, but the 'Save the Date' (like a telegram), invitations, favour boxes, orders of service and 'Thank You' cards were all printed by me in a consistent style and colours.

DE: I’ve always looked through the pile and put the best sheet on top!

What's your biggest ever mistake?

BB: Leaving the paper grippers in place on a small treadle press while proofing some type. I smashed a lot of Gill Sans Cameo type. It will probably never be re-cast and I was gutted!

DE: A quarter of a ton of paper and two days of time went to waste when I wrongly backed up a sheet. It was caused by a combination of the job being wrongly laid out and me turning the paper over the wrong way. When the waste paper man came he said the weight of paper was small fry - about three weeks beforehand he’d picked up a job that had gone wrong for another printer, and he’d collected six tons!

Why do you think people find printing so interesting?

DE: The public virtually never went behind the scenes where printing work was done. It kept untrained people away from dangerous machinery. A customer would turn up with their copy jotted down on a fag packet, then return a few days later and collect an attractive deckle-edged card with airbrushed border with the wording beautifully laid out and printed. How did they do it? Magic!

BB: It’s the same thing that drew me to printing to start with - the breadth of avenues to explore. On top of that printing has a very rich heritage and a great sense of camaraderie.

Do you have a sense of being heir to Johannes Gutenburg?

BB: Probably not. It's a great comment that Gutenberg could walk in to a letterpress printers today and get to work - things have improved gradually but not so much that it is completely alien. That said, his aim was much more noble than mine: to produce for the first time books in volume. Mine is simply to interest myself! I suspect that history will review our period and see blogging and self-expression online as the continuation of Gutenberg's work rather than just printing.

DE: Gutenberg’s invention, movable type, was leading-edge technology in its day - so much so that he went bust, unable to pay back the money that one of his investors had put in. Depending on which way you look at it, would Gutenberg still be sitting back and enjoying the craft aspect of his invention (i.e. hand setting type) or would he be at the innovative forefront of digital printing technology?

What do you think of digital print?

BB: It has a place in printed things. I'm not a letterpress fascist. I think the world would be nicer with more letterpress printers, but it's amazing to see what can be done digitally and I'm glad more people can print.

DE: Digital printing is amazing technology - but the skill is in the systems and software in the machine, not in the mind and hands of the person running the machine.

How has the technology changed over your life?

BB: I’ve never worked in print - always been a great enthusiast rather than professional printer. In my nine years with letterpress I have seen a lot of letterpress-only printers close as the last of the local jobbing letterpress printers shut down.

DE: At printing college in Manchester in the 1970s one of our lecturers once said 'If it works, it’s obsolete!' In other words, technology marches on and if something new had just been rolled out as the latest labour or time saving-gizmo, there was already something in the pipeline to supersede it. The firm I started work at was very old fashioned, with much hand-set type and every sheet to be printed had to be individually fed into the machine by hand. The other firms around had mostly machine typesetting and auto-feed presses. Then came paste-up, where letters, lines and chunks of text were glued onto a blank layout sheet to create a business card, invoice or page of text, which was then photographed to create a negative or positive from which printing plates were made. Following that, film and computer technology allowed text and other pages to be created on-screen. Now graphics files can be created which at the press of a button can be emailed to printers in, say, China, and the computer-to-plate technology then produces plates which are put on the machine, sheets run off. In a nutshell, printing has evolved from a skilled trade to a massively automated industry where much of the skill has been taken out of the operatives’ hands and is more in the computer and automation technology.

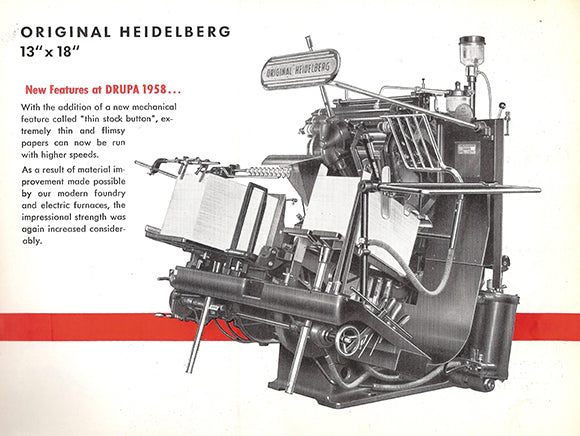

Why are Heidelberg platen presses so good?

DE: Savvy printers had a range of machinery because of the advantages of certain machines. The Heidelberg platen had a British rival - the Thompson-British Auto Platen - and some preferred it to the Heidelberg. Thompsons were built in Manchester, with some also produced in Coventry. My old firm once had to have a job printed at a place that had a Thompson because the stock was too thick for the Heidelberg to handle. With the Thompson it was easier to get the right impression level, particularly on very thick stock. We also had a hand fed platen and when another local printer had a job that went wrong - they missed a logo off - we were able to feed opened out booklets into our machine and save the day for them. Their automatically fed machines wouldn’t pick the booklets up. The customer was none the wiser! It's horses for courses though and the Heidelberg had more advantages over the Thompson than vice versa. So, to answer your question more precisely, Heidelbergs were considered by many to be the best all-round machine. They’ve remained in use because spare parts are still available.

BB: I agree with David's suggestions on the Thompson Platen. That's probably the choice for the printer happy to have a more complex machine, but better results. The beauty of the Heidelberg is that they set the standard, and there are perhaps hundreds of printers in the UK that could happily run a letterpress job on a Heidelberg today. They are remarkable machines, and I wonder what the world would be like if they had continued to push letterpress as a modern printing method when others were moving to litho.

Printing is a unique branch of the graphic arts - printers are part-engineer, part-mechanics, part-copyist and part-artists. How do you see yourself?

BB: I think that's the draw for me! Though I'm very much an observer and enthusiast rather than practitioner.

DE: In the heyday of letterpress the various stages of getting words onto paper was separated into composing, machine printing, and binding, each of which was further divided. At a medium sized printing firm, say 25 to 50 staff, there would be:

Why is there so much interest in letterpress printing?

DE: The craft and its traditions going back 500 years, the skill, the precision, working with words, working with your hands, and the beauty of the final products.

BB: What's not to like?! To be a really good jobbing printer , you need to be at least competent at: writing with style; visual design with imagaination; mechanical engineering; planning and management; and all that before we start on the art of printing itself. I can't think of a more demanding craft. There are so many possibilities to explore! On top of that you actually handle and produce something rather than something that exists only on a screen.

What is your all time favourite printing press?

BB: It would have to be the Halifax-built Arab platen press. Very much a product of its time and place but still working hard. I meet printers now that undertake commercial work on an Arab, it's a machine that's very adaptable, versatile and does the same job today as it was designed for 141 years ago!

DE: There were and are many fascinating machines used in the printing trade. It’s not a press as such, but my favourite has to be the Linotype machine

Why is there so much interest in letterpress printing?

DE: The craft and its traditions going back 500 years, the skill, the precision, working with words, working with your hands, and the beauty of the final products.

BB: What's not to like?! To be a really good jobbing printer , you need to be at least competent at: writing with style; visual design with imagaination; mechanical engineering; planning and management; and all that before we start on the art of printing itself. I can't think of a more demanding craft. There are so many possibilities to explore! On top of that you actually handle and produce something rather than something that exists only on a screen.

What is your all time favourite printing press?

BB: It would have to be the Halifax-built Arab platen press. Very much a product of its time and place but still working hard. I meet printers now that undertake commercial work on an Arab, it's a machine that's very adaptable, versatile and does the same job today as it was designed for 141 years ago!

DE: There were and are many fascinating machines used in the printing trade. It’s not a press as such, but my favourite has to be the Linotype machine - a composing department consisted of machine composition, hand composition, proofing, page make-up, imposition;

- the printing department (the ‘Rattle and Squeak Brigade’) running platens and cylinder machines, both hand-and auto-fed;

- the bindery which both started and finished the job, cutting the paper to size before printing, then doing any cutting, folding, collating, gathering, padding, gluing, trimming, and any other processes necessary to finish the job.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.